XIAC latest news: <07 January 2026>

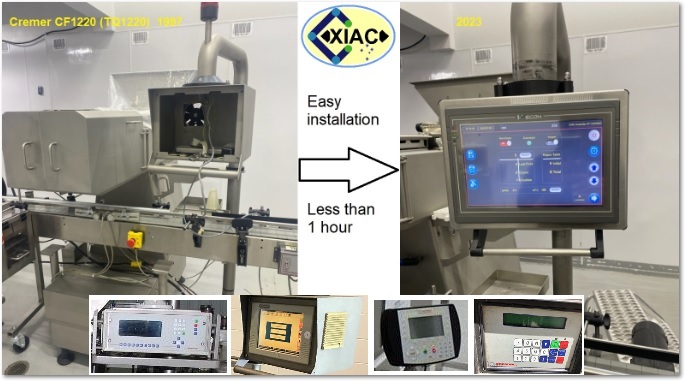

XIAC latest news: <15 December 2023>

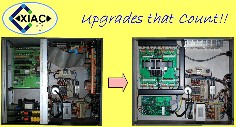

Please contact us for more information regarding the products we provide for your tablet counting equipment. This could be retrofits, upgrades, refurbishments or XIAC extensions for Cremer, Swiftpack or King machines.

XIAC latest news: <04 July 2023>

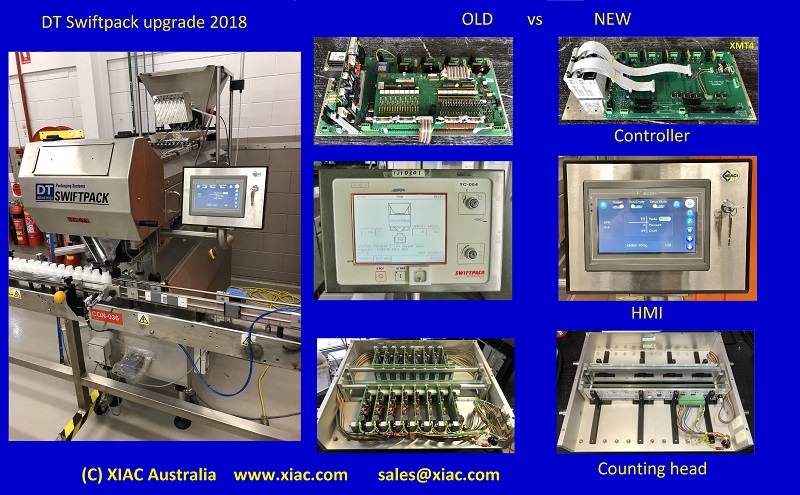

With great success trialed in our Swiftpack upgrades, this economical upgrade, requires only the processor board (PLC) and HMI or HHT (Hand Held Terminal) to be replaced.

Summary:

- Installation within 1 hour

- No cable replacement

- Maintain 100% counting accuracy

- High speed Mitsubishi PLC

- 10-15% increased output

Benefit from increased efficiency due to:

- AFC (Automatic Feed Control)

- sDSG (Smooth Down Stream Gating) up to 65BPM with Speed Nozzles

- Quick bottle reject times

- Staged memory flaps (reduced nozzle blockage)

- Double product-Double count (accurate counts even when products overlap)

- BPM timer to maintain consistent production output

Optional:

- Fallen bottle or bottle up/side/down detection (also available for clear bottles)

- Jammed bottle detection

- Dust-Extreme upgrade for detection unit (excellent performance even during extremely dusty product runs)

- Sine wave vibrator drive for smoother and quieter product run

- Easy-Clean memory flap cylinder nuts and buffers

NOTE: XIAC's proprietary "Dust-Extreme" tablet detection sensors are unrivalled in the market when it comes to counting extremely dusty products. While other sensors become inaccurate or fail after 30 minutes or 1 hour, our sensors keep on going and generally only need cleaning once a day.

Common error messages on the CF-1220 tablet counter are: Channel defect, Output defect, COM1 defect, COM2 defect, Upload error 90 (9), PWM control, Frequency Control, RAM defect, Channel defect 1, Product too long / overlap, Overcount, Undercount, Not separated, Double detection

, Nozzle error (blocked nozzle)

Common issues Cremer CF1220 counter: Overcount followed by undercount, Undercount followed by overcount, Products shooting out of the counting channels

, Nozzle vibration not working well, Machine up/down control not working, Broken tablets in bottle, Product falling out of nozzle when bottle is indexing

, Product jamming in nozzle, Product jamming in channel insert, Running (counting) gummies, Product not transporting well on vibratory trays

, Products piggyback (capsules)

, Screen not working, Screen with lines / stripes, Screen faint

XIAC latest news: <09 February 2023>

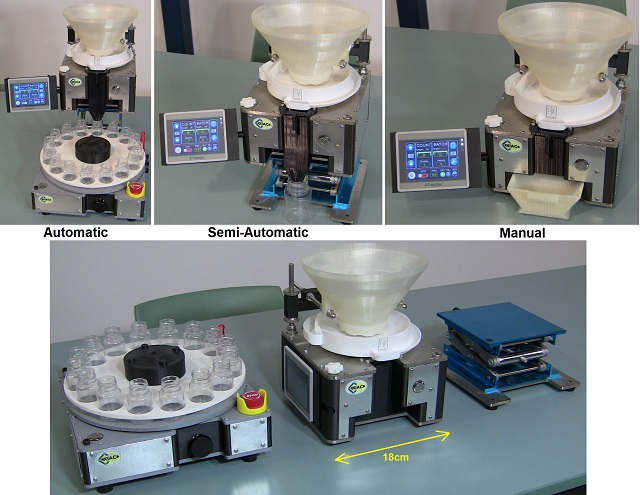

Excellent choice for Pharmacies, Universities, Hospitals, start-up companies, large Pharmaceutical companies, counting of sample / stability batches

!! Unrivalled in all aspects !!

- Compact tablet counter, small footprint

- Light weight

- Quiet

- Accurate (100% in most cases)

- Versatile

- Environmentally friendly, uses little power, can run on small solar panel.

- Tablets, pills, caplets, hardgel capsules, softgel capsules, Toothpaste Tablets, confectionary, seeds etc.

- Industial performance (up to 15cm/sec)

- User friendly (with recipe structure for product and bottle)

- Servo vibration system with AFC

- Automatic, Semi-Automatic, Manual and Check-counting

- Bottle reject function

- Hybrid counting sensor with our very own "Dust-No-Problem!" detection protocol (no dust extraction required).

- Suitable for jars, bottles, tubs, pouches, stand-up pouches, punnets etc etc.

- Counts accurately from tiny poppy seeds up to size 000 softgels

- Designed and manufactured in Australia

In Automatic mode, the MicroXF can also be connected to a bottle conveyor, bucket elevator or form-fill-seal machine (stick packs).

XIAC latest news: <03 February 2022>

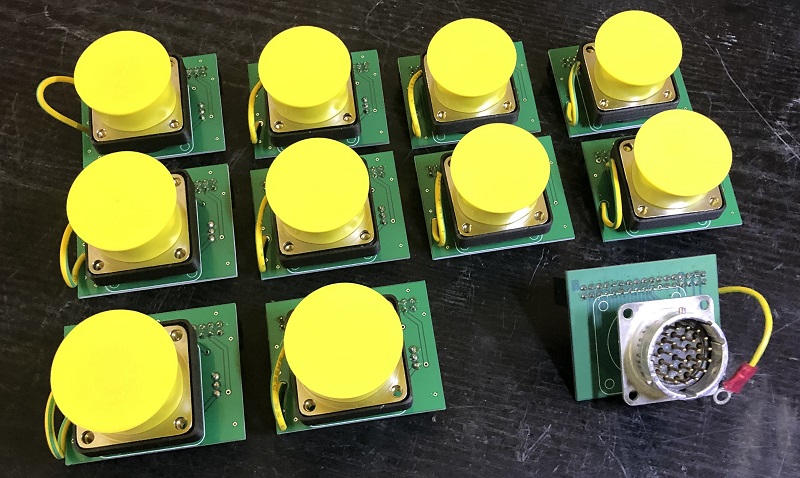

The controllers feature:

- Drop-in replacement for the old TC8 or TC12 controller

- Optional electronics for the sensor head (counting head)

- Optional set of cables for slides unit, sensor head etc

- 100% counting accuracy

XIAC latest news: <17 July 2021>

XIAC latest news: <01 July 2021>

Click picture to watch YouTube video

XIAC latest news: <02 April 2021>

CF1220Guru latest news: <25 December 2019>

Swiftpackman latest news: <12 October 2018>

Previously:

<

21 February 2018>

The drop-in replacement for the old Swiftpack MT3 terminal is now available. This new controller uses a state-of-the-art Mitsubishi PLC together with

a colour touch screen terminal.

Also available: <

4 June 2017>

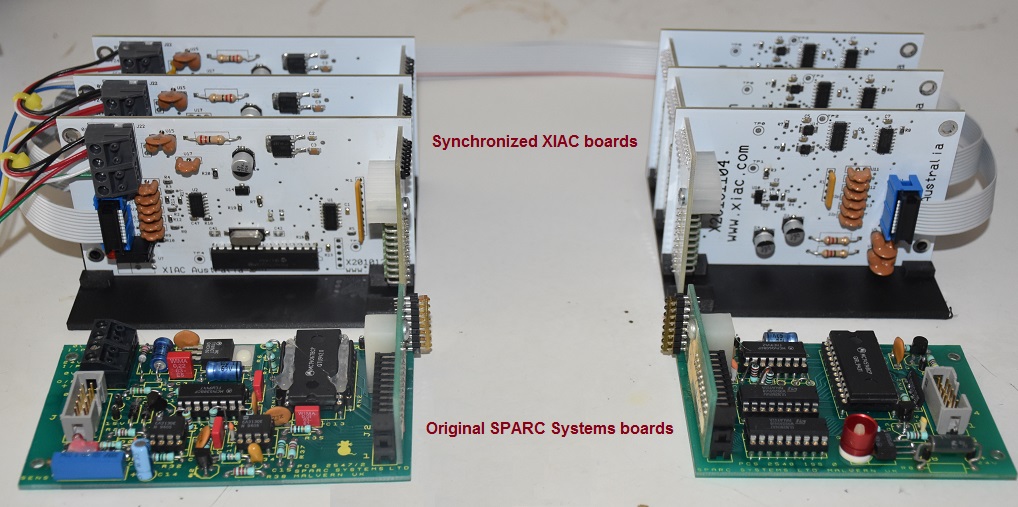

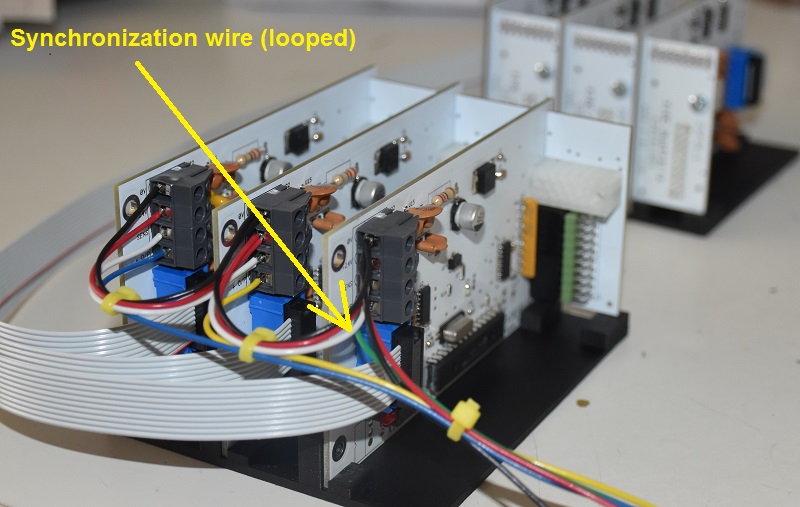

We now supply Synchronized counting heads for the Swiftpack machines (25PSR & 35PSR).

Synchronizing the counting heads has the advantage that should light be detected in a channel that came from

a neighbouring channel, this light will not result into "ghost" counts.

Ghost counts are faulty count pulses that lead to undercounted bottles. The original SPARC Systems boards (and to a lesser extend the un-synchronized XIAC boards) suffer from this problem.

Synchronized heads are the best option for your Swiftpack machine.

Download Sensor documentation for 25PSR replacements

Download Sensor documentation for 35PSR replacements

YES, we also repair Swiftpack MT3 terminals!

These terminals are used in a wide variety of counting machines, including the SPC type Swiftpack Tablet Counters from 4 to 16 channels, single and duplex machines. Duplex machines usually run with 16 channels

split over 2 chutes (8 channels per chute) to fill 2 bottles at a time.

Also Available <

June 2016>

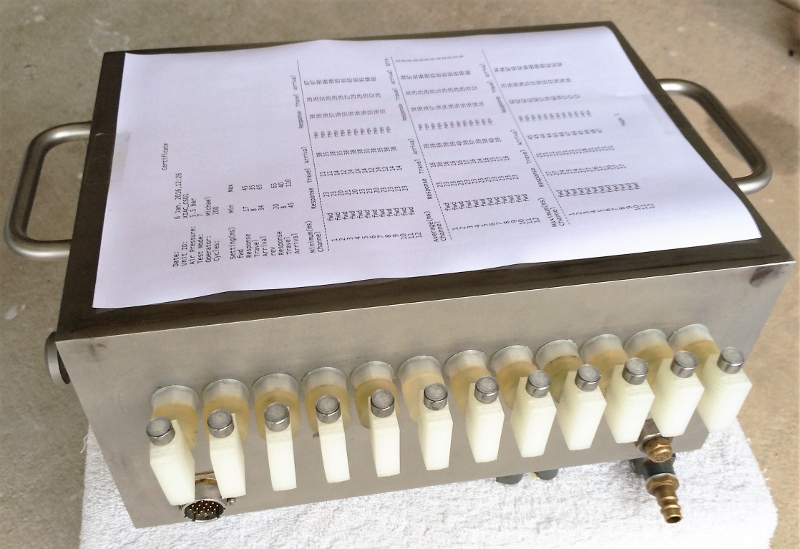

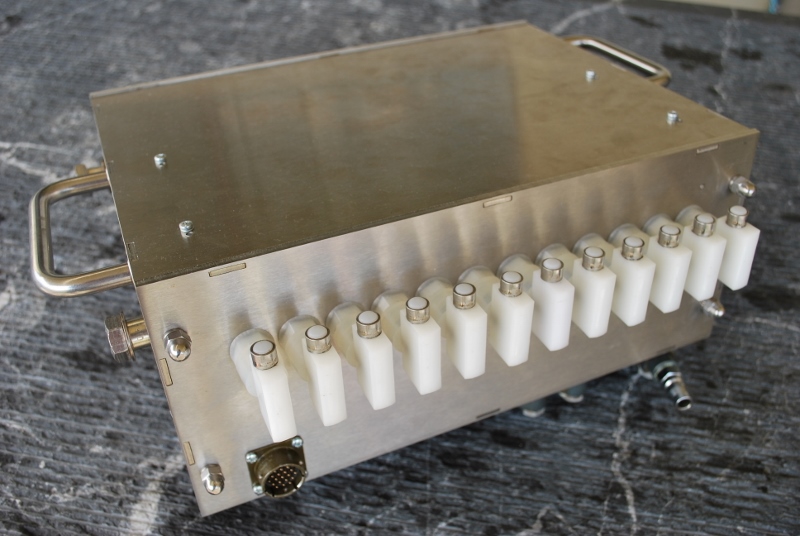

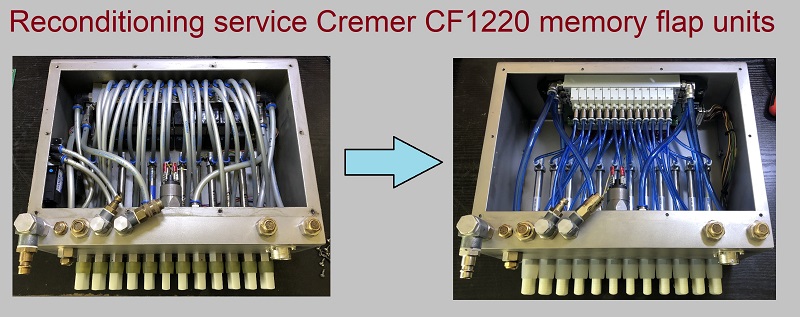

We professionally recondition and supply Memory flap units for the Cremer CF1220 tablet counters.

The new XIAC design comes optionally with internal electronics to validate each and every cylinder stroke and an iPhone app for configuration.

The reconditioned CF1220 memory flap units use approximately 45% less compressed air!! All units (new or reconditioned) come with a certificate of compliance for the cylinder timings.

Download CF1220 Installation validation manual here

Download CF1220 iPhone app manual here

Also available

<

February 2016>

For over 6 years, XIAC provides upgrades for the King TB4 tablet counters. Our latest design is a compact controller with colour touch screen terminal.

Comes standard with product particle filter; parameters for softgel capsules and user restrictions that can be enabled or disabled.

Download King TB4 Installation validation manual here

Also Available:

<

December 2012> This kit is for tablet counter manufacturers that desire the best sensors for

their tablet counting machinery. The kit consists of a 6 channel

detector, 6 channel emitter and 6 channel amplifier unit. Of course

it incorporates our popular "Dust-No-Problem!"

detection

algorithm.

Contact

us now to enquire about the "Dust-No-Problem!"

upgrade kit..

This easy to install kit comes with 100%

money back guarantee and 1 year warranty.

Our

latest upgrade features the Cremer CF-830 Type II Tablet Counter

Click images to enlarge.

Cremer CF-830; King TC-8; King TC-12; King TB4; King

TB5; Swiftpack SPC Upgrades

We

can upgrade and/or retrofit these machines:

Click to send email

XIAC is

well known for solutions in industrial automation. We do electronic

repairs, electronic design, develop software, improve/expand current

solutions. Our main customers use pharmaceutical tablet and capsule

counting machinery.

Industrial

Electronic Design : We are experts in designing sensors to detect all sorts of products. This includes, but is not limited, to tablets and capsules. We also design PLC protocols to accurately count your products. PLC software includes Mitsubishi, TwinCAT and Allen Bradley. Our protocols can also be converted to common languages like C, C++, Pascal or assembler. We're currently working on a "Counter-In-A-Box" unit. This unit is for machine manufacturers that want to design a new tablet counter but do not want to worry about the electronic aspects. XIAC Australia designs sensors, emitters, sensor amplifier modules, vibrator control boards and can link everything together with a PLC and TouchScreen terminal.

Industrial

service & maintenance: We

service many manufacturing and packaging equipment around the Sydney

area. For example:

King

TB-5, TB-4, King Dispensa; We also supply tailor

made electronics

to accurately count clear

gel capsules with

these counters.

King

TC-8 Tablet counter (service, repair & upgrades)

King

TC-12 Tablet counter (service,

repair & upgrades)

Swiftpack

machines that have "SPARC SYSTEMS LTD" PSR25 (with and

without automatic gain control) (ELSEN25PSR)

sensors in the sensor head. PCS 2547/1 & PCS 2548 ISS 0. We

supply new “Dust-No-Problem!” sensors world-wide. New

sensors have 46dB electronic dust compensation and are exclusively

available through XIAC Australia.

Most

Cremer machinery including CF-830, CF-1230, CF-1220

(service, repair & upgrades)

Swiftpack / Kalish SPC and DT type HMI and controller upgrades

Calibration

service: We

calibrate King, Swiftpack, Cremer and several label pre-counting

equipment.

Total

Electronic Makeovers (Retrofitting):

Pharmaceutical

Tablet counters like King TB4, TC8 or Cremer CF830 usually still

look like new even after more than 20 years. The problem is usually

not mechanically but electronically. The old electronic parts are no

longer supplied or have lead times over 8 weeks. To save production

down-time, we can deliver a package to completely strip all

electronics in these machines and replace it with state-of-the-art

modern technology electronics. This is much cheaper than buying new

machinery and more reliable than purchasing second hand machinery.

Machines that had a total electronic makeover will last for another

15 to 20 years! See also our Products

and Project

XIAC Australia tablet counter services, upgrades and retrofits. With XIAC,

your tablet counter is always in top condition!

Download Sensor documentation for 25PSR replacements

Download Sensor documentation for 35PSR replacements

YES, we also repair Swiftpack MT3 terminals!

These terminals are used in a wide variety of counting machines, including the SPC type Swiftpack Tablet Counters from 4 to 16 channels, single and duplex machines. Duplex machines usually run with 16 channels

split over 2 chutes (8 channels per chute) to fill 2 bottles at a time.

Also Available <

June 2016>

We professionally recondition and supply Memory flap units for the Cremer CF1220 tablet counters.

The new XIAC design comes optionally with internal electronics to validate each and every cylinder stroke and an iPhone app for configuration.

The reconditioned CF1220 memory flap units use approximately 45% less compressed air!! All units (new or reconditioned) come with a certificate of compliance for the cylinder timings.

Download CF1220 Installation validation manual here

Download CF1220 iPhone app manual here

Also available

<

February 2016>

For over 6 years, XIAC provides upgrades for the King TB4 tablet counters. Our latest design is a compact controller with colour touch screen terminal.

Comes standard with product particle filter; parameters for softgel capsules and user restrictions that can be enabled or disabled.

Download King TB4 Installation validation manual here

Also Available:

<

December 2012> This kit is for tablet counter manufacturers that desire the best sensors for

their tablet counting machinery. The kit consists of a 6 channel

detector, 6 channel emitter and 6 channel amplifier unit. Of course

it incorporates our popular "Dust-No-Problem!"

detection

algorithm.

Contact

us now to enquire about the "Dust-No-Problem!"

upgrade kit..

This easy to install kit comes with 100%

money back guarantee and 1 year warranty.

Our

latest upgrade features the Cremer CF-830 Type II Tablet Counter

Click images to enlarge.

Cremer CF-830; King TC-8; King TC-12; King TB4; King

TB5; Swiftpack SPC Upgrades

We

can upgrade and/or retrofit these machines:

Click to send email

XIAC is

well known for solutions in industrial automation. We do electronic

repairs, electronic design, develop software, improve/expand current

solutions. Our main customers use pharmaceutical tablet and capsule

counting machinery.

Industrial

Electronic Design : We are experts in designing sensors to detect all sorts of products. This includes, but is not limited, to tablets and capsules. We also design PLC protocols to accurately count your products. PLC software includes Mitsubishi, TwinCAT and Allen Bradley. Our protocols can also be converted to common languages like C, C++, Pascal or assembler. We're currently working on a "Counter-In-A-Box" unit. This unit is for machine manufacturers that want to design a new tablet counter but do not want to worry about the electronic aspects. XIAC Australia designs sensors, emitters, sensor amplifier modules, vibrator control boards and can link everything together with a PLC and TouchScreen terminal.

Industrial

service & maintenance: We

service many manufacturing and packaging equipment around the Sydney

area. For example:

King

TB-5, TB-4, King Dispensa; We also supply tailor

made electronics

to accurately count clear

gel capsules with

these counters.

King

TC-8 Tablet counter (service, repair & upgrades)

King

TC-12 Tablet counter (service,

repair & upgrades)

Swiftpack

machines that have "SPARC SYSTEMS LTD" PSR25 (with and

without automatic gain control) (ELSEN25PSR)

sensors in the sensor head. PCS 2547/1 & PCS 2548 ISS 0. We

supply new “Dust-No-Problem!” sensors world-wide. New

sensors have 46dB electronic dust compensation and are exclusively

available through XIAC Australia.

Most

Cremer machinery including CF-830, CF-1230, CF-1220

(service, repair & upgrades)

Swiftpack / Kalish SPC and DT type HMI and controller upgrades

Calibration

service: We

calibrate King, Swiftpack, Cremer and several label pre-counting

equipment.

Total

Electronic Makeovers (Retrofitting):

Pharmaceutical

Tablet counters like King TB4, TC8 or Cremer CF830 usually still

look like new even after more than 20 years. The problem is usually

not mechanically but electronically. The old electronic parts are no

longer supplied or have lead times over 8 weeks. To save production

down-time, we can deliver a package to completely strip all

electronics in these machines and replace it with state-of-the-art

modern technology electronics. This is much cheaper than buying new

machinery and more reliable than purchasing second hand machinery.

Machines that had a total electronic makeover will last for another

15 to 20 years! See also our Products

and Project

XIAC Australia tablet counter services, upgrades and retrofits. With XIAC,

your tablet counter is always in top condition!

Download CF1220 Installation validation manual here

Download CF1220 iPhone app manual here

Also available

<

February 2016>

For over 6 years, XIAC provides upgrades for the King TB4 tablet counters. Our latest design is a compact controller with colour touch screen terminal.

Comes standard with product particle filter; parameters for softgel capsules and user restrictions that can be enabled or disabled.

Download King TB4 Installation validation manual here

Also Available:

<

December 2012> This kit is for tablet counter manufacturers that desire the best sensors for

their tablet counting machinery. The kit consists of a 6 channel

detector, 6 channel emitter and 6 channel amplifier unit. Of course

it incorporates our popular "Dust-No-Problem!"

detection

algorithm.

Contact

us now to enquire about the "Dust-No-Problem!"

upgrade kit..

This easy to install kit comes with 100%

money back guarantee and 1 year warranty.

Our

latest upgrade features the Cremer CF-830 Type II Tablet Counter

Click images to enlarge.

Cremer CF-830; King TC-8; King TC-12; King TB4; King

TB5; Swiftpack SPC Upgrades

We

can upgrade and/or retrofit these machines:

Click to send email

XIAC is

well known for solutions in industrial automation. We do electronic

repairs, electronic design, develop software, improve/expand current

solutions. Our main customers use pharmaceutical tablet and capsule

counting machinery.

Industrial

Electronic Design : We are experts in designing sensors to detect all sorts of products. This includes, but is not limited, to tablets and capsules. We also design PLC protocols to accurately count your products. PLC software includes Mitsubishi, TwinCAT and Allen Bradley. Our protocols can also be converted to common languages like C, C++, Pascal or assembler. We're currently working on a "Counter-In-A-Box" unit. This unit is for machine manufacturers that want to design a new tablet counter but do not want to worry about the electronic aspects. XIAC Australia designs sensors, emitters, sensor amplifier modules, vibrator control boards and can link everything together with a PLC and TouchScreen terminal.

Industrial

service & maintenance: We

service many manufacturing and packaging equipment around the Sydney

area. For example:

King

TB-5, TB-4, King Dispensa; We also supply tailor

made electronics

to accurately count clear

gel capsules with

these counters.

King

TC-8 Tablet counter (service, repair & upgrades)

King

TC-12 Tablet counter (service,

repair & upgrades)

Swiftpack

machines that have "SPARC SYSTEMS LTD" PSR25 (with and

without automatic gain control) (ELSEN25PSR)

sensors in the sensor head. PCS 2547/1 & PCS 2548 ISS 0. We

supply new “Dust-No-Problem!” sensors world-wide. New

sensors have 46dB electronic dust compensation and are exclusively

available through XIAC Australia.

Most

Cremer machinery including CF-830, CF-1230, CF-1220

(service, repair & upgrades)

Swiftpack / Kalish SPC and DT type HMI and controller upgrades

Calibration

service: We

calibrate King, Swiftpack, Cremer and several label pre-counting

equipment.

Total

Electronic Makeovers (Retrofitting):

Pharmaceutical

Tablet counters like King TB4, TC8 or Cremer CF830 usually still

look like new even after more than 20 years. The problem is usually

not mechanically but electronically. The old electronic parts are no

longer supplied or have lead times over 8 weeks. To save production

down-time, we can deliver a package to completely strip all

electronics in these machines and replace it with state-of-the-art

modern technology electronics. This is much cheaper than buying new

machinery and more reliable than purchasing second hand machinery.

Machines that had a total electronic makeover will last for another

15 to 20 years! See also our Products

and Project

XIAC Australia tablet counter services, upgrades and retrofits. With XIAC,

your tablet counter is always in top condition!

Click images to enlarge.

Cremer CF-830; King TC-8; King TC-12; King TB4; King TB5; Swiftpack SPC Upgrades

Click to send email

Industrial Electronic Design : We are experts in designing sensors to detect all sorts of products. This includes, but is not limited, to tablets and capsules. We also design PLC protocols to accurately count your products. PLC software includes Mitsubishi, TwinCAT and Allen Bradley. Our protocols can also be converted to common languages like C, C++, Pascal or assembler. We're currently working on a "Counter-In-A-Box" unit. This unit is for machine manufacturers that want to design a new tablet counter but do not want to worry about the electronic aspects. XIAC Australia designs sensors, emitters, sensor amplifier modules, vibrator control boards and can link everything together with a PLC and TouchScreen terminal.

Industrial service & maintenance: We service many manufacturing and packaging equipment around the Sydney area. For example:

King TB-5, TB-4, King Dispensa; We also supply tailor made electronics to accurately count clear gel capsules with these counters.

King TC-8 Tablet counter (service, repair & upgrades)

King TC-12 Tablet counter (service, repair & upgrades)

Swiftpack machines that have "SPARC SYSTEMS LTD" PSR25 (with and without automatic gain control) (ELSEN25PSR) sensors in the sensor head. PCS 2547/1 & PCS 2548 ISS 0. We supply new “Dust-No-Problem!” sensors world-wide. New sensors have 46dB electronic dust compensation and are exclusively available through XIAC Australia.

Most Cremer machinery including CF-830, CF-1230, CF-1220 (service, repair & upgrades)

Swiftpack / Kalish SPC and DT type HMI and controller upgrades

Calibration service: We calibrate King, Swiftpack, Cremer and several label pre-counting equipment.

Total Electronic Makeovers (Retrofitting): Pharmaceutical Tablet counters like King TB4, TC8 or Cremer CF830 usually still look like new even after more than 20 years. The problem is usually not mechanically but electronically. The old electronic parts are no longer supplied or have lead times over 8 weeks. To save production down-time, we can deliver a package to completely strip all electronics in these machines and replace it with state-of-the-art modern technology electronics. This is much cheaper than buying new machinery and more reliable than purchasing second hand machinery. Machines that had a total electronic makeover will last for another 15 to 20 years! See also our Products and Project

XIAC Australia tablet counter services, upgrades and retrofits. With XIAC, your tablet counter is always in top condition!